Gill Oil Debris Sensors – A Case Study

See the condition of your equipment at any given time with Gill Oil Debris Sensors.

A Gill 4212i’s Oil Debris Sensor was installed on a critical machine from a coal plant in the Mpumalanga area for real-time wear and temperature monitoring.

The Gill 4212i condition sensor has a visual display and comes with the following features:

- 4 Measurement options

- 3 Output options

- Captures and retains ferrous debris

- Continuous real-time monitoring

- Easy installation

- Low cost of ownership

The sensor was installed on a Discard Conveyor Gearbox, operating with ISO 320 lubricant. On installation of the sensor, the gearbox oil was drained but the gearbox was not flushed as requested. Metal particles were obviously left behind.

Channels set on the Gill device included Fine Metal Wear, Coarse Metal Wear and an Oil Temperature Alarm set at 80°C (which will flash red on the Gill sensor’s visual display). Any indication of Coarse Metal Wear would be a red flag, which would normally be associated with larger failures such as a chipped tooth on one of the gears. Acceptable behaviour or readings on Fine Metal Wear stage (orange) would a slow increase to reach full stage over a period of 12 months.

The sensor was installed on a Discard Conveyor Gearbox, operating with ISO 320 lubricant. On installation of the sensor, the gearbox oil was drained but the gearbox was not flushed as requested. Metal particles were obviously left behind.

Channels set on the Gill device included Fine Metal Wear, Coarse Metal Wear and an Oil Temperature Alarm set at 80°C (which will flash red on the Gill sensor’s visual display). Any indication of Coarse Metal Wear would be a red flag, which would normally be associated with larger failures such as a chipped tooth on one of the gears. Acceptable behaviour or readings on Fine Metal Wear stage (orange) would a slow increase to reach full stage over a period of 12 months.

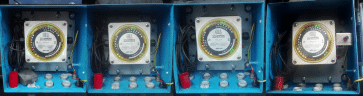

The 4 x 9V alkaline battery setup was used in this particular case study.

Several readings were taken over a period of two months, from the Gill Sensor’s display. During this time, there were no changes to the Coarse Metal Wear and Temperature Alarm indicators. The Fine Metal Wear indicator increased from 2 to 5 steps (lights.)

These readings were compared with the results from an oil sample taken after the last reading. The Oil Analysis Report indicated that the Fe (Iron) count increased– mirroring the reading from the Gill Sensor. Furthermore, the sample confirmed that the maximum wear particle size in the oil sample was 20 microns, supporting the sensors reading of no coarse particles.

With the Gill Sensor installed, real-time oil monitoring is possible, and not only with every oil sample taken which could range from 30 days to 3 months apart. Gill Sensor readings are taken from a visual display, which encourages the general inspection of equipment wear by attending technicians. An added benefit is that the magnetic properties of the sensor remove wear particles from the oil during normal operation, acting as a filter in the system, but most of all – it is affordable.

It is clear that Gill Sensors could be the first line of defence in your Lubrication Management practice.

Learn more about the Gill Oil Sensors – or contact our skilled staff by filling in the form below.

Featured Products

Contact Us for More Information

"*" indicates required fields