Every Tenth Saves Money

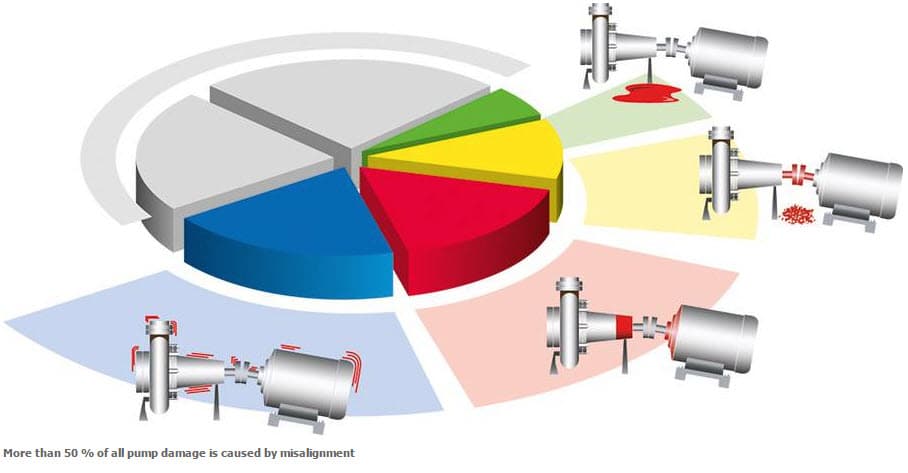

Did you know that more than fifty percent of all pump damage is caused by misalignment? Laser measurement systems and service provided by Yellotec do not only ensure a longer service life of seals and bearings, they also increase energy efficiency.

Hard to believe: If the misalignment offset is reduced from 0.5 mm to 0.05 mm, the average interval between failures improves from 4 to unbelievable 200 months. Hence, by a factor of 50.

Not many people know that more than 50 percent of all machine damage is caused by incorrect shaft alignment. This percentage may seem unusually high, however, the numbers speak for themselves.

What happens if the alignment is inaccurate? A misalignment of a few tenths of a millimeter leads already to machine overload and causes machine vibrations. Excess machine loading can result in bearing damage, seal wear, coupling damage, or machine vibrations that drastically reduce the service life of the different components and – in the worst case – cause expensive production losses. Last but not least, the energy consumption increases. Thus, operating companies can save money with accurate shaft alignment.

It can be that simple

The main problem of mechanical measuring methods is that they align the surface of two couplings only. If these surfaces have a paint or rust layer, they cannot be correctly aligned anymore.

A laser system, however, determines the actual rotational axis by rotating the shafts – the surface quality has no influence. For example, a shaft can also be aligned using a dial gauge.

The problem: If the measuring arms sag one tenth of a millimeter, measuring with a precision to the hundredth does not make sense. Rounding and readout errors accumulate quickly. Only an expert knows which errors occur and how to handle them to ensure a good measurement result. It looks much easier than it actually is. However, using a laser measurement system does not require any expert skills.

It only takes three steps to complete a measurement

1. Enter dimensions

2. Rotate shafts

3. Read out results

Done.

Laser alignment

Yellotec offers a whole series of shaft alignment systems covering a wide area of applications – from simple coupling systems, frequent pumps and motors, to complex systems with multi-stage turbines and compressors. Yellotec use Pruftechnik hardware and software – PRUFTECHNIK invented laser alignment.

Real success stories

The former Hoechst Group was able to reduce the number of pump repairs by 30 % by using our laser alignment systems. with seals lasting significantly longer.

As laser-optical shaft alignment can also lower the vibration level during machine operation, an oil refinery in Great Britain was able to reduce the number of vibration alarms from 700 to 400. As result, the mineral oil and natural gas company could also reduce the number of other failures and increase the service life of seals and bearings.

A sealing manufacturer achieved an amazing result: The average operating time between two consecutive machine failures was drastically extended with the help of accurate shaft alignment. When a machine runs with a relatively large offset, failure will definitely occur within a few months.