A New Revolution in Kiln Monitoring as of 2021

The first Kiln monitoring system that Yellotec installed is still in operation since 2013 which makes it a very reliable solution. The system detected faults and prevented catastrophic failures and saving our customers millions of Rands since the installation. The Kiln Monitoring system is inexpensive compared to possible failures and is very low in maintenance cost. The team at Yellotec are very proud to build and supply the complete solution for continuous kiln shell monitoring.

A recap of our previous article:

In the previous article that was written in 2014, we looked deeper into the world’s first Kiln Shell Monitoring System based on Microbolometer Infrared Camera Technology.

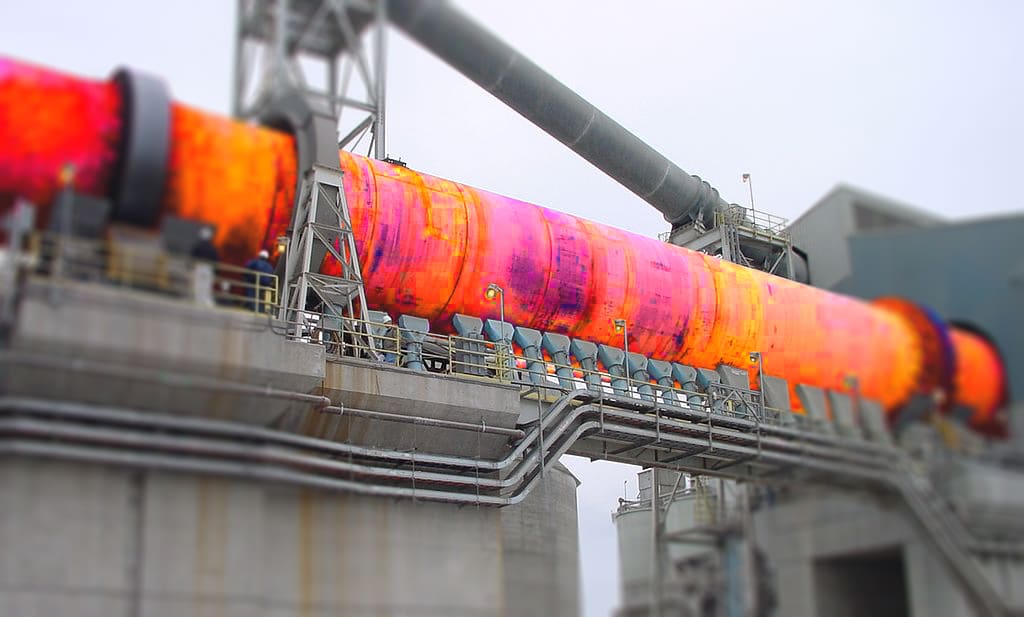

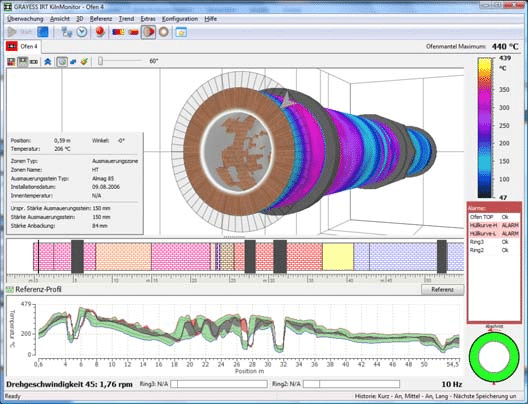

IRT KilnMonitor® is a full-featured computer system that allows you to monitor, process and trace data from rotary cement kilns. Unlike existing solutions, it is based on standard microbolometer radiometric infrared cameras, as used in a variety of different applications.

The system has major advantages over other methods. Including, reduced maintenance costs, high-resolution thermal profiles, and internal refractory profiling via 3D modelling, significantly reduced capital costs, and maximised up times – the revolution has finally started.

Key features of the Virtual 3D Kiln Display:

- Kiln “pipe” with infrared image on the surface.

- The kiln is rotating at a real speed.

- Rings and other shadow zones.

- Position of the top-kiln.

- Real coordinates ruler with the kiln refractory and shadow zone’s structure.

- And many more!

Staying up to date with Kiln Monitoring:

Kiln monitoring is important, and you must monitor the degradation of the material and detect damaged or fallen bricks. The easiest way to do this is to monitor the temperature of the kiln shell. Infrared technology has been favoured in the past to perform this task. Sophisticated user interfaces have been designed to make the data easier to analyse and understand. Recently, high demands have led to the development of more complex products that do a lot more than just measure temperature.

The Thermal Imaging Cameras of the Kiln monitoring system provide accurate temperature measurements in a visual format, with high detector resolution. This enables the user to extend equipment life and allow money-saving on maintenance programs. This infrared technology contributes to improving production in quality and quantity while reducing downtime and energy consumption.

Benefits of Kiln Monitoring:

- Higher field of view for new larger kilns (up to 4 thermal cameras with 110º view angle)

- Higher resolution (up to 3.200 measuring points per line) for refractory detail

- High sensitivity to identify even the smaller temperature changes and hot spots.

- Easy integration and communication of all data to Plant Control System.

- Pre-wired and pre-tested for an easy installation.

- Calibration checks are not required.

- Fibre optic communication

- Training and commissioning support by a highly qualified and experienced team.

What Yellotec offers in terms of Kiln Monitoring Technology:

Yellotec partnered with Grayess, who is an Infrared Thermography Software Developing Specialist with software that is:

- easy to use,

- highly sophisticated,

- high compatibility,

- ease of data exchange and

- has more than 3000 installations worldwide!

Today, it is impossible to imagine the building industry without cement. Cement is one of the most valuable and useful products in the world. It is an important part of mortar, concrete, manufacturing and more. Cement production is a complex process, in which one of the steps consists of blending limestone with other components in big rotary furnaces. These furnaces or kilns are a critical asset of a cement production plant, heating their contents to temperatures up to 1,500 °C. There is a risk of overheating, which can cause serious damage to the kiln shell. It is important to monitor this delicate heating process and prevent possible damage to the kiln. Thermal imaging cameras are great to use in this situation as they are used to measure temperatures on a 24/7 basis.

The IRT KilnMonitor® system is an advanced computer system that allows cement production operators to monitor, process and trace data from several kilns at once. IRT KilnMonitor® systems protect your plant and machinery constantly. Yellotec is proud to be able to provide this dependable turnkey solution. We have trust in the brands that we represent and the solutions we can create with our partners. If you would are interested in Kiln Monitoring equipment. Please feel free to contact us by visiting, calling, emailing or filling in the contact form and one of our experienced team will get back to you with everything you need.

"*" indicates required fields