A new revolution in Kiln Monitoring

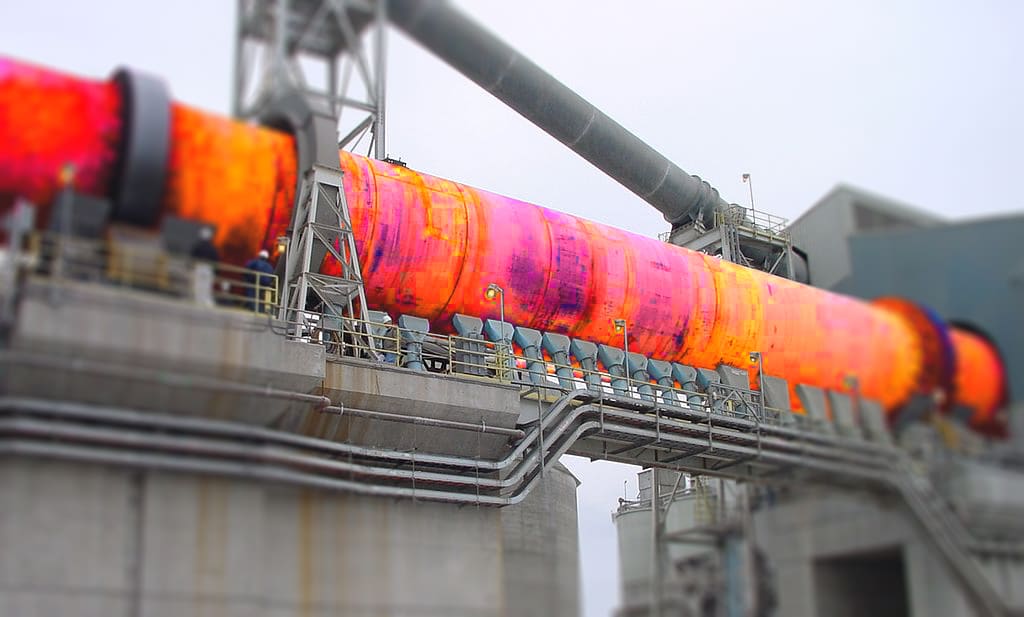

The World’s first Kiln Shell Monitoring System based on Microbolometer Infrared Camera Technology.

As of 6th December 2021, Yellotec has added an updated article on kiln monitoring. Please feel free to visit the article to see what is happening as of 2021/2022

IRT KilnMonitor® is a full-featured computer system that allows you to monitor, process and trace data from rotary cement kilns. Unlike existing solutions, it is based on standard microbolometer radiometric infrared cameras, as used in a variety of different applications.

Historically rotary kiln owners used Line scanners to protect expensive kilns against failure and overheating caused by refractory thinning and damage. This method incurred high capital and maintenance costs, with lengthy repair turnaround times. All of the above are now eliminated with the new IRT KilnMonitor® designed by Yellotec and Grayess – (a leading German software development company), and now the first such Kiln System has been installed on a rotary Cement Kiln in Italy.

The system has major advantages over other methods; from reduced maintenance costs, high-resolution thermal profiles, AND internal refractory profiling via 3D modelling, significantly reduced capital costs, and maximised up times – the revolution has finally started.

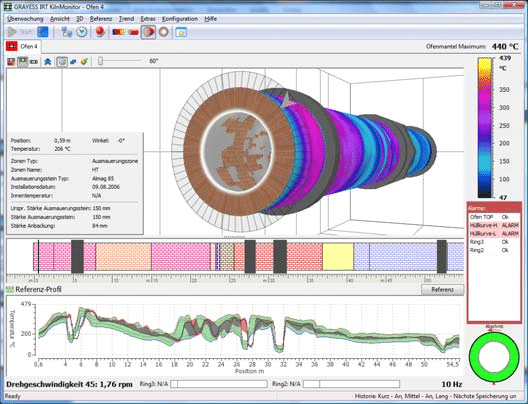

Here are features of just one of four options of data viewing – The Virtual 3D Kiln Display:

- Kiln “pipe” with infrared image on the surface.

- The kiln is rotating at a real speed.

- Rings and other shadow zones.

- Position of the top kiln.

- Real coordinates ruler with the kiln refractory and shadow zones structure.

- The brick refractory with calculated thickness.

- Coating with calculated thickness.

- Possibility to view from different angles and look inside the kiln.

- Section view with detailed kiln information at the section.

- Split by refractory zones view (also works in section and end views).

- Colourized refractory zones.

Yellotec is proud to be the Grayess partner for Africa and we will work tirelessly to provide these needed improvements and cost savings to Kiln owners/operators in South Africa. Please download the brochure to read the full specification and features of the system.