ASCEND™ to Lubrication Excellence

Many organizations strive for lubrication excellence, a challenging yet attainable goal for a dedicated and determined team. The concept of lubrication excellence has been somewhat ambiguous, but Noria has clarified it with the Ascend™ methodology. This approach serves not only as a definition but also as a powerful tool for evaluating, designing, implementing, and controlling the transformation toward lubrication excellence. Ascend™ acts as the North Star, illuminating the path to this achievement.

Identifying the starting point on the journey to lubrication excellence requires evaluating current practices against lubrication best practices, known as the Optimum Reference State (ORS) according to Noria. Once the gap is identified, it is crucial to establish an optimal road map that ensures resources, effort, and time are allocated to initiatives that yield the highest return on investment.

This requires prioritizing based on lubricant lifecycle logic and the impact of improvements on machine reliability and other organizational objectives. Once the process begins, it is essential to measure progress, continue the transformation plan, identify deviations, and ensure that improvements are sustainable.

Ascend™ represents an essential evolutionary advancement over the traditional radar (or spider) chart, which has long been the standard for evaluating lubrication processes. By integrating this new approach throughout the lubricant lifecycle, alignment with ISO 55001 and ICML 55.1 standards can be achieved. Furthermore, it meets the business objectives of many users seeking to implement a lubrication program that enhances plant reliability.

The Ascend methodology is built on years of proven field experience, attentiveness to industry needs, and alignment with both lubrication practices and international asset management standards. It is driven by our commitment to innovation and continuous improvement.

Lubrication Lifecycle Stages

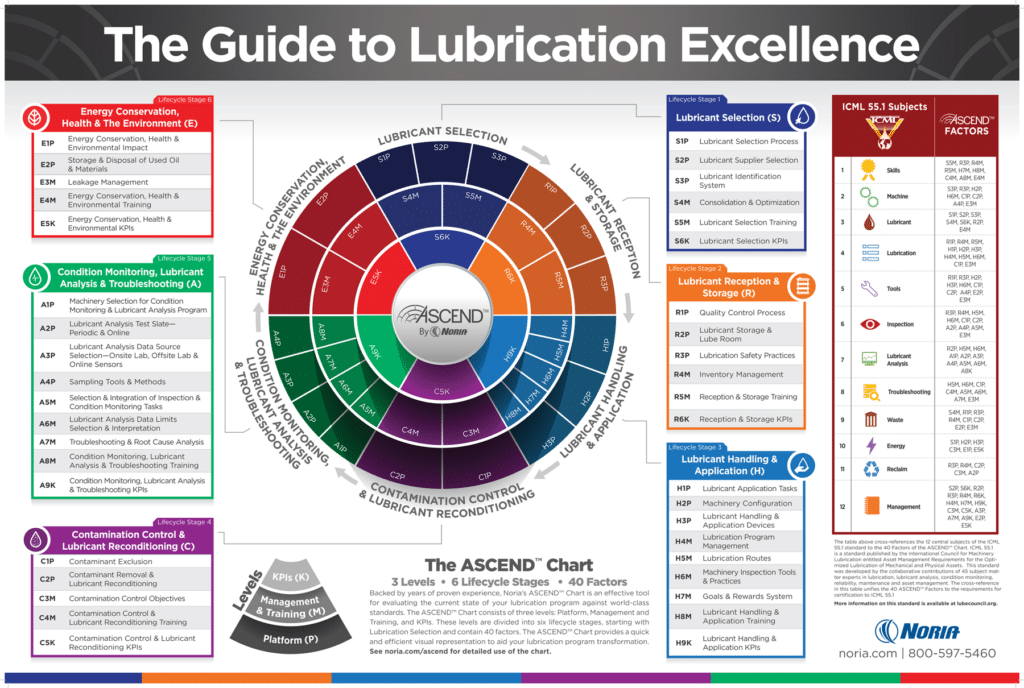

Ascend utilizes six lifecycle stages in chronological order: selection, reception, application, management, analysis, and disposal. This methodology emphasizes the importance of each stage and its impact on lubrication excellence, machine reliability, and asset management.

For the first time, following the lubricant lifecycle allows users to correlate their daily activities at each stage with fundamental business objectives, demonstrating how each stage functions individually and as part of the whole in executing correct lubrication principles.

Ascend highlights the importance of selecting the right lubricant, tailored to the machine’s requirements and operational context. This includes ensuring the lubricant arrives in the correct condition, is stored properly, and is applied to the machinery at the right place and frequency. Precision lubrication also involves using the correct amount, applying it with the right tools, and ensuring it is done by a knowledgeable and skilled person. Additionally, contamination control of lubricants and using lubricant analysis as a metric for lubrication state and overall machine health are fundamental needs.

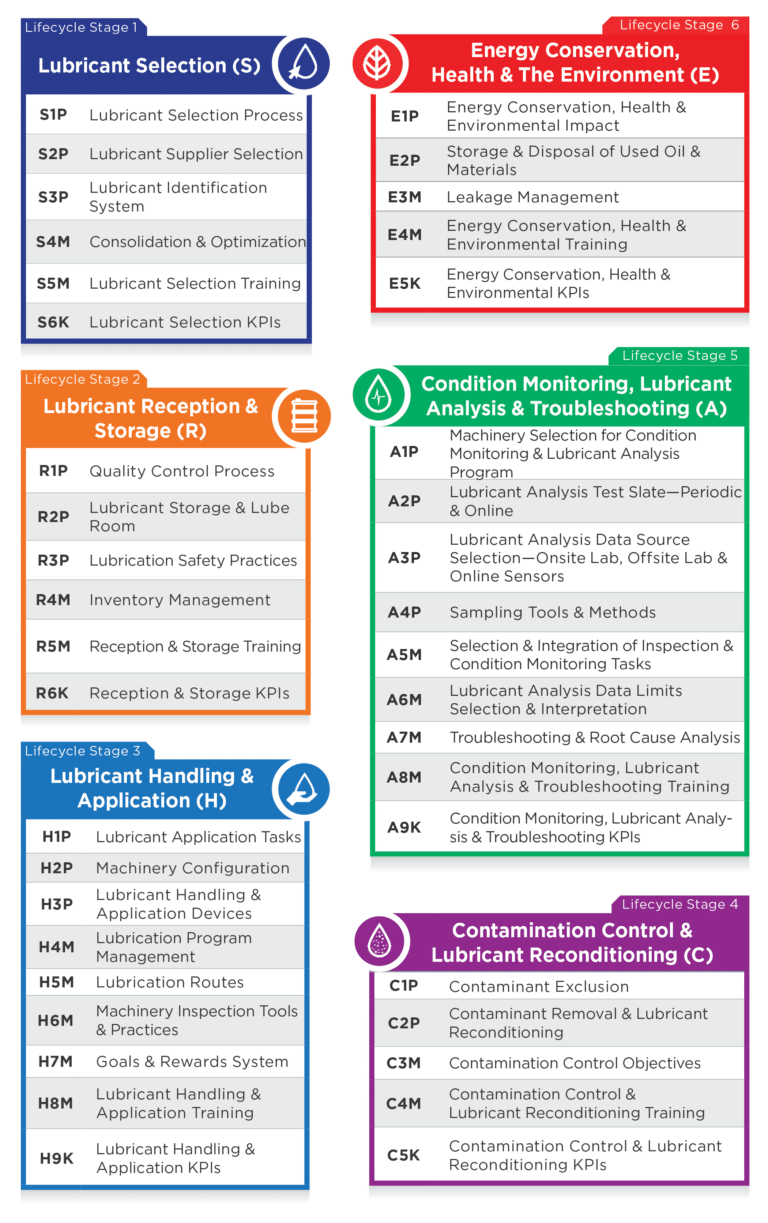

The life cycle stages are shown as angular wedges on the Ascend chart:

- Lubricant selection (S)

- Lubricant reception and storage (R)

- Lubricant handling and application (H)

- Contamination control and lubricant reconditioning (C)

- Condition monitoring, lubricant analysis and troubleshooting (A)

- Energy conservation, health and the environment (E)

Factors and Management Levels

In the Ascend™ methodology, lubrication activities throughout the lubrication process lifecycle are divided into 40 factors (see Table 1. Ascend Factors). Each factor is linked to one or more of the 12 areas specified in clause 5.0 of the ICML 55.1 standard for Asset Management Requirements for the Optimized Lubrication of Mechanical Physical Assets.

It is important to note that these 40 factors do not all carry the same weight in the design and implementation of the lubrication strategy. To emphasize and clarify these differences, the factors are arranged into three levels (see Figure 1):

- Platform (P)

- Management and Training (M)

- Performance Indicators (K)

Platform factors serve as the foundation of the program, aimed at controlling risks, ensuring performance, and sustaining the program over the long term. These tactical factors need to be implemented first.

Management and Training factors involve activities that provide the necessary resources, planning, scheduling, and condition monitoring of lubricants and machines. This level includes staff education and skills development, encompassing day-to-day lubrication activities supported by all platform factors. Key Performance Indicators (KPIs) allow measurement of the efficiency and effectiveness of lubrication program activities, facilitating continuous improvement.

Each factor has an alphanumeric code for easy identification. The code consists of three parts: the first digit refers to the Lubrication Lifecycle Stage, the second digit is the factor number within the stage, and the third digit denotes the Management level. For example, the S3P element is the third factor in the Lubricant Selection Stage and is at the Platform level.

Using Ascend to Track the Transformation

The Ascend™ methodology employs Six Sigma’s DMAIC (Define, Measure, Analyze, Improve, and Control) tool to evaluate the maturity of the lubrication program, starting from an established baseline and progressing through the transformation plan. The Optimum Reference State (ORS) is defined according to the ICML 55.1 standard. ORS compliance is assessed through inspections, measurements, verifications, and interviews.

The Ascend methodology analyzes discrepancies between required ORS performance and current performance to prioritize the implementation plan based on business objectives and reliability. During the assessment phase, Ascend not only evaluates the maturity of each factor based on compliance (completeness) but also provides specific improvements aimed at meeting the ORS for each of the 40 lubrication process factors. It identifies critical actions to ensure sustainable implementation with appropriate controls.

Ascend assigns maturity levels to lubrication process factors using a traffic light code: compliance below 30% is red, compliance between 30% and 90% is yellow, and compliance of 90% or more is green (see Table 2. Maturity of the Ascend Factors).

The Global Compliance Level of Ascend (ACL) serves as a comprehensive indicator of the lubrication program’s maturity. The ACL is not a simple average of the 40 factors; it is calculated using a proprietary mathematical algorithm that incorporates a Balanced Score Card (BSC) of the lubrication process and the maturity of each factor. The active ACL value is displayed in the center of the Ascend Chart.

The Ascend Chart

The Ascend™ methodology is visually represented by a chart consisting of the six stages of the lubrication process life cycle and the three management levels, showing the degree of maturity and compliance with ICML 55.1 standards.

Implementation Priority and Execution Plan

The Ascend Chart intuitively guides implementation based on the maturity of factors at different levels. It also features a built-in mathematical algorithm based on the Balanced Score Card (BSC) of the lubrication process, considering the sequence, relative weight, and maturity of each factor to calculate the Priority Impact Number (PIN). The PIN helps establish a transformation road map by determining which factors to implement first, based on lifecycle logic, their contribution to business objectives, and plant reliability.

The Business Case for Ascend

Numerous real-world case studies published in Machinery Lubrication magazine support the implementation of lubrication excellence. A successful case study requires validation of each process step based on investments made relative to financial returns within a designated timeframe.

During the Assessment Phase, Ascend™ explores the costs of the lubrication program and estimates the impact of current practices on maintenance budgets, operating budgets, and overall productivity. This analysis seeks to identify the financial impact of current lubrication practices and is part of the cost-benefit analysis necessary to justify investments in lubrication excellence. Financial analysis tools such as Internal Rate of Return (IRR), Net Present Value (NPV), and Payback Period (PP) are used to develop a business case for management approval.

This proactive approach to implementing lubrication excellence makes improvement projects less risky and justifies the necessary investments.

Lubrication Excellence Transformation

Each improvement initiated based on the initial Ascend evaluation report contributes to achieving ORS compliance and enhances the maturity of factors within the program. Ascend™ features integrated simulation tools that demonstrate the impact of individual initiatives on improving Factor maturity within the ACL global compliance indicator.

Whether utilizing the PIN or following the straightforward logic of Ascend, the journey toward lubrication excellence should focus on immediately enhancing priority factors, particularly concentrating efforts on red and yellow elements at the Platform level. By identifying these priorities, improvement projects can strategically target a few factors at a time, ensuring optimal resource allocation and clear measurement of project outcomes from start to finish. These targeted initiatives often yield economic benefits and increased reliability, bolstering project credibility, team trust, and facilitating the implementation of subsequent phases.

Some organizations recognize the criticality of lubrication excellence and opt for a comprehensive transformation project of their global lubrication processes to achieve accelerated benefits. Drawing from years of proven industry experience, we provide sophisticated tools, software, and tailored recommendations to support organizations in executing such projects efficiently, ensuring they stay on the shortest path to success without unnecessary deviations or distractions.

Interested? Get in touch.

"*" indicates required fields