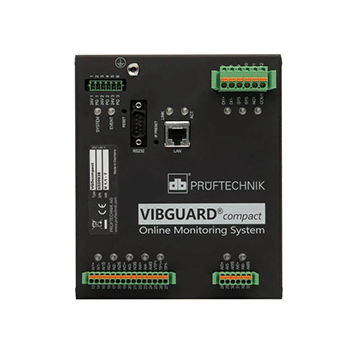

VIBGUARD Compact

The VIBGUARD compact offers 6 measuring channels for continuous real-time monitoring of fast and highly dynamic motion sequences. Thus VIBGUARD compact fulfils in particular the high maintenance requirements of critical single aggregates, characterized by high availability, high aggregate value, complex drives, and changing operating conditions.

Online Condition Monitoring for Single Aggregates

All 6 measuring channels are designed as highly dynamic analogue input channels and can be equipped with either standard ICP vibration sensors or with voltage input signals for process variables. They provide in-depth diagnostic data such as time signals or envelope signals, and up to 6 characteristic values such as vibration characteristic or bearing condition.

VIBGUARD compact can therefore ensure reliable monitoring – even with frequently changing operating conditions. It can thus protect against unplanned downtimes, secure production, and sustainably increase single aggregate efficiency.

The VIBGUARD compact ‘Intelligent Event Recorder’ stores relevant results, fully automatically and continuously, thus providing the fundamental basis necessary for comprehensive machine diagnostics. Its bidirectional Modbus TCP interface enables instant VIBGUARD compact Online Condition Monitoring System integration to your Industry 4.0 environment.

Whether pre-installed in an IP 65 compact housing, or as a switch cabinet system module; the VIBGUARD compact is perfect for diagnostic condition monitoring of extruders, large fans, multiphase or vacuum pumps, turbocompressors, mill stands, or centrifuges.

Key features

- 6 fully synchronous measuring channels for continuous data acquisition

- Observation of up to 6 operating conditions

- Characteristic value trend storage with adjustable data reduction and Intelligent Event Recording

- Especially for single aggregates with high aggregate value, complex drives, and changing operating conditions

Specifications

Technical data

| Number of channels | 6 (either ICP/U/I) |

| synchronous measuring channels | all |

| Speed inputs | 1 |

| Digital inputs | 1 |

| Digital outputs | 2 relay outputs |

| Dynamic | 110 dB for 24 Bit |

| FFT number of lines | Up to 102,400 |

| Interfaces Ethernet | 100Mbit, 1x RS232 |

| Services | Modbus TCP, Modbus RTU |

| Data storage | 1 GB |

| Supply voltage | 24V / 0.5A |

| Housing | Aluminum IP22 or housing |

Product Enquiry

"*" indicates required fields