Additional Info

Features

-

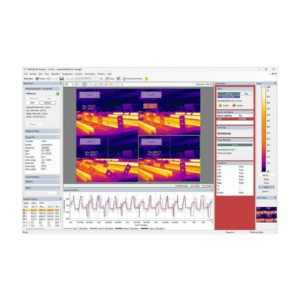

Setup and visualization of up to nine A320 camera’s for stand-alone applications like on-line monitoring and control

-

Setup of alarms and I/O configuration for Digital out

- Setup of synchronized signals for recording of image sequences in ResearchIR.

-

Draw a Mask to cut out part of image not to be analyzed

-

Saving of Images and Image Control

- Setting of scheduled Events and other E-Mail options

-

Synchronies Camera to Internet Time servers

The concept of IrMonitor enables the use of several IR cameras and pan-&-tilt systems for monitoring large areas of industrial plants. The system is based on software which administrates the operation of the cameras and analyses the thermal images that are recorded. Automation Technology offers several packages with all known features for tasks of thermographic monitoring. These packages can be combined without problems and this is why IrMonitor is a flexible solution which covers all areas of applications of infrared monitoring.

Early detection of fires

This thermographic solution is a fully automatic early fire detection system designed to pinpoint and visualise blazes in industrial plants like waste bunkers or open depots. IR monitor detects critical temperature developments and this is why it is a useful aid in fire-fighting.

Early detection of refractory failure

This solution is used as a preventive maintenance system to automatically monitor highly stressed materials such as foundry ladles. By analysing the temperature distribution on the exterior of the ladle, any imminent refractory lining failure can identify in good time.

Monitoring in Petrochemical plants

The turnkey petrochemical detection system monitors industrial facilities to pinpoint gas or liquid leaks – speedily, without contact and with precision. Such defects occur frequently ondefective seals on fittings, flanges and capacitors. Until now, defects of this nature have been identified by traditional means by measuring fluctuations in pressure at various points. This method, however, takes time to identify leaks because a certain amount of the medium needs to have escaped first before any noticeable drop in pressure can be detected.

With Automation Technology’s thermographic solution, such escape points can be detected substantially quicker either because the medium is detected or because the escape point warms or cools. The difference in the length of time it takes to identify defects can be crucial, especially in the case of combustible gases or liquids, if explosions or combustion are to be prevented.