Additional Info

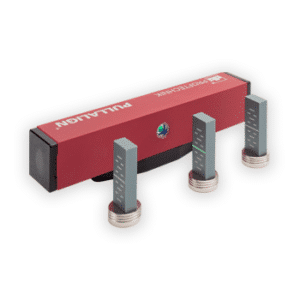

An aligned pulley system reduces pulley and belt wear, vibration of machinery, which in turn leads to improved machine performance. Good pulley alignment reduces unscheduled downtime, and improves the reliability of your equipment. PULLALIGN is tailor-made for the job as it is easy to use, and requires only a single operator. The units mount onto virtually any pulley face, making it the ideal partner for most pulley alignment jobs. PULLALIGN utilizes the proven and patented OPTALIGN reflected beam principle for maximum angular resolution. This allows for accurate and reliable readings.

A laser line is projected onto the reflector mounted on the opposite pulley. Horizontal angle, vertical angle and offset corrections are visually determined by the position of the laser line on both the laser and reflector. These alignment parameters are monitored simultaneously. Good alignment is achieved

when the transmitted laser line and the corresponding reflected laser line harmonize with the respective reference line.

Due to the powerful magnets of the laser and reflector, the tool mounts to the inside or outside faces of any pulley or sprocket drive. Its unique design ensures that there are no small parts that can get lost. The result is reliable and accurate readings that wire or straightedge alignment methods cannot match.

PULLALIGN can measure long spans with any size pulley. This easy-touse tool enables a single operator to complete the alignment in minutes without any training. PULLALIGN comes in a durable case.

PULLALIGN benefits

- Efficient one-man operation

- Shows offset, vertical and horizontal angle simultaneously

- Reflected beam technology doubles the distance, enhancing accuracy

- Only one laser for complete alignment

- Reduces down time and energy costs

- Reduces vibration and belt noise

- Prolongs belt, pulley and bearing life

- Time saving method as no cross-checking required

- Easier to use than conventional methods

- Supplied in a case or pouch

- No training required