Marine

Yellotec Marine currently provide Vibration and Thermographic Baseline and Pre-refit surveys, together with ongoing Remote Analysis/reporting service on over 14000 machines per month to over 75 LNG/LPG vessels . This service includes free 24/7 support, and full calibration service. In addition, we can provide Online Vibration Monitoring systems, Laser Alignment services and products, and Thermal Surveys and cameras.

Yellotec are ABS accredited external specialists.

Yellotec are ABS recognised providers for our condition monitoring services that include Vibration Monitoring, Thermography and Oil Analysis and Tribology.

Full Remote Diagnosis

Overview

The vast majority of plant on a vessel can be monitored via a low cost, scheduled manual inspection, using handheld instrumentation, and the data analysed remotely. This removes the cost of requiring staff (qualified Level 3 VM with 2-3 years field experience) on each vessel to carry out analysis of data – (Our engineers have an average of 10 years’ experience).

Vibration Analysis – Regular inspections by ships engineering staff generate automatically uploaded route information which is added to the remote vessel database. These are then analysed by our engineers for necessary action and reports are then sent to the vessel and ship management.

How does it work?

- Yellotec engineers will visit the vessel, perform a full baseline survey, create an on-board database, train the crew in data collection and basic analysis, and generate a report on all initial machine conditions.

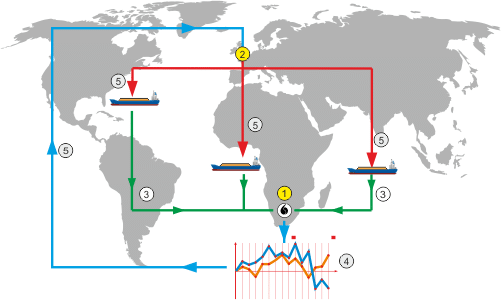

- The vessel database is then held at Yellotec (1) and company headquarters (2).

- Plant is manually inspected by vessel technicians and the results automatically uploaded to Yellotec (3).

- Results are analysed and Reliability based Maintenance reports automatically generated for both vessel and management (4). These will contain details of trending, fault severity, all actions required (immediate, medium and long term), and vessel compliance (data collection and fault repair).

- Results can be integrated into fleet CMS for live monitoring of work carried out, and post repair readings.

Online Monitoring

Where more critical machines (Generators, compressors, turbines etc) are fitted with continuous online monitoring, this data can also be included in the Remote Analysis Service.

By implementing a full remote diagnostic service the following benefits can be derived:

- Replacement of standard Planned Maintenance operations with an optimised ISO based Reliability based Maintenance Programme.

- Minimisation of risks and costs, and maximisation of safety, uptime, reliability and asset value.

- Reducing downtime, parts inventories

- Optimisation of refit planning

- Automated report generation

- Centralised reporting and database system with integration into clients CMMS system.

- Long term trending of machine condition and vessel compliance

- In-house expertise to derive maximum results from in initial baseline measurements, rather than time consuming building of and depending on trends.