Yellotec saves Client US$48M

Online assets undergo continuous real-time monitoring, with Yellotec personnel stationed in on-site and offsite control centres for diligent assessment, analysis, and reporting on the collected data. Remote assets are reported on weekly and monthly, with urgent changes in machine condition reported immediately.

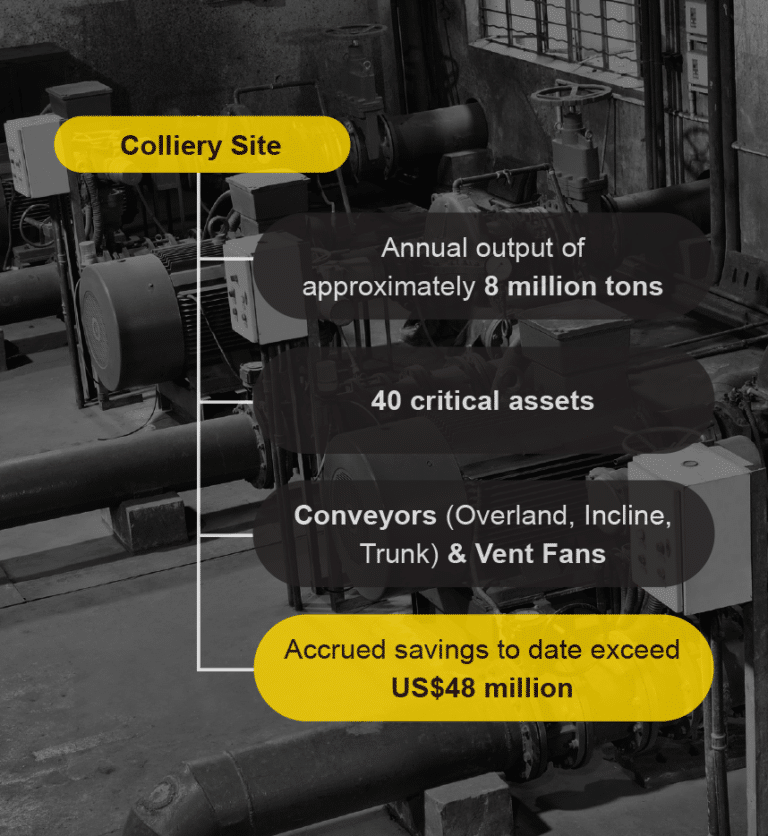

One such customer site is a colliery involved in both underground and open-cast operations, with an annual output of approximately 8 million tons. This client entrusted Yellotec with the installation and commissioning of online vibration monitoring on 40 critical assets, including conveyors (Overland, Incline, Trunk), and Vent Fans.

As our partnership progresses into its third year of operation, the client has conducted independent assessments of all findings, meticulously calculating and verifying the realized value. Since its inception in 2021, the accrued savings to date exceed US$48 million.

Below is a case study of one such finding for this client.

Site: Colliery

Machine: VSD Drive motor on Incline Conveyor

Rating: 750Kw

Problem Category: Bearing Defect caused by Electrical Fluting

Value Realised: US$ 386 000

Diagnosis:

Alarm due to high vibration was observed on the NDE Motor Bearing. Harmonics of Outer Race Defect frequency at 177,6 Hz with side bands spaced at FTF (cage frequency) 10,67 Hz evident in the demodulation and acceleration spectral data comparisons. Gradual increase in spectral band trends noted. Also noted was a high frequency vibration in the region of 5 kHz with side bands spaced at 2X LF, confirming that the Motor is running on a VSD and suspected fluting as a secondary effect.

Notification was created and raised while it was still in initial stage and at low priority. As the defect progressed, the relevant Forman was notified and the status was changed to high priority.

Recommendation:

Initially it was recommended to ensure adequate bearing lubrication; however, no improvement was noted and as the defect progressed it was recommended to replace the Motor. The motor was then sent off site for inspection and repair.

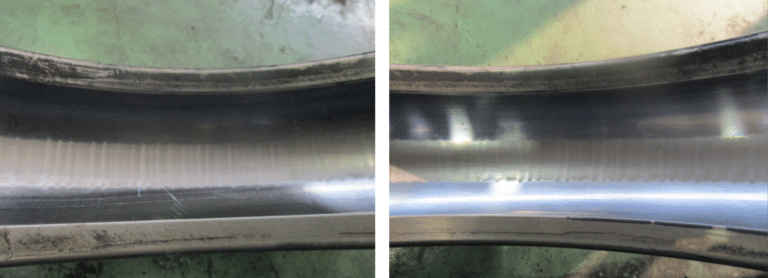

Findings:

The NDE bearing was cleaned and opened for inspection. The bearing outer race show clear signs of damage due to electrical fluting. the NDE bearing defect identified by Condition Monitoring was a result of electrical discharge through the NDE bearing. The erosion of the raceway resulted in contamination of the grease. Continued operation with this condition would have resulted in premature failure.

Conclusion:

Specific attention should be paid on drives that are equipped with Variable Speed Drives (VSD’s), this includes Motor shaft grounding brushes that should be in place to discharge electrical currents to prevent secondary damage on motor bearings.

Lets assist you, chat to our expert team today!

"*" indicates required fields