Additional Info

Proper repair and reconditioning of turbines, combustion engines, compressors and pumps require an exact alignment measurement of rotors, crankshaft and camshaft bores, cylinder bores and crosshead guides.

CENTRALIGN Ultra RS5 is a laser alignment system designed for the measurement and alignment of bores and internal elements of rotating machines such as bearing rings, diaphragms, nozzles, inner shells and turbine casings with tops on or off. It offers a far more convenient and accurate alternative to the traditional methods using piano wires, micrometers and cumbersome theodolite telescopes.

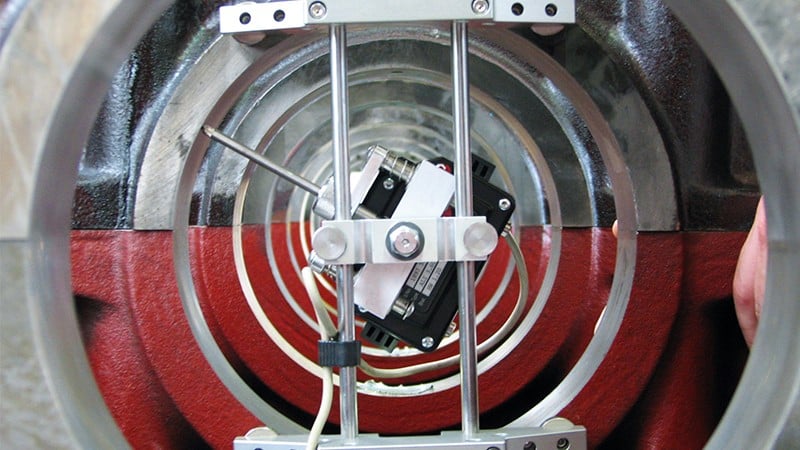

The CENTRALIGN Ultra RS5 measurement method uses a laser emitter which is mounted at one end of the machine and shoots through the approximate center of the bores. The laser beam serves thereafter as the measurement reference line. The sensor is mounted in the bore to be measured using the patented universal pointer brackets. The exact rotational centerline of the bore is then determined by simply rotating the sensor and the bracket head around the inside of the bore. The sensor records positional deviations relative the laser and sends the measured data to the ROTALIGN Ultra computer. The computer processes this information along with the machine dimensions involved to calculate the exact centerline position. When using the long range laser, the distance between laser and sensor increases up to 50 meters.